suku cadang Crusher maénkeun peran krusial dina ngajaga efisiensi jeung reliabilitas parabot crushing. Tanpa perawatan ditangtoskeun, komponén kawas nuaci crusher or bagian crusher dampaktiasa gancang kaluar, ngarah kana perbaikan anu mahal sareng telat operasional. Pangropéa teratur ngirangan ngagem sareng ngajamin bagian-bagian ieu tiasa dianggo sacara optimal dina kaayaan anu nungtut. Ukuran proaktif, sapertos beberesih sareng pamariksaan, ngabantosan ngaidentipikasi tanda awal karusakan, manjangkeun umur komponén kritis. Usaha anu ngutamakeun pangropéa henteu ngan ukur ngahémat biaya tapi ogé ngahontal produktivitas anu langkung saé sareng ngirangan downtime.

Takeaways konci

- Cék rutintiasa ngirangan masalah alat ku 30%. Rencanana pamariksaan rutin pikeun mendakan ngagem awal.

- Ngabersihan kokotor tina bagian crusher ngeureunkeun clogs na overheating. Beberesih mindeng mantuan bagian tahan leuwih lila.

- Jieun arencana pangropéakalawan cék, beberesih, jeung oiling. Ieu ngabantuan ngahindarkeun breakdowns sarta ngajaga hal ngajalankeun ogé.

- Ngagunakeun minyak katuhu lowers gesekan jeung eureun overheating. Pariksa sistem minyak pikeun ngajaga suku cadang jalan lancar.

- Ngajarkeun pagawe kumaha ngalakukeun pangropéa. Pagawe anu dilatih tiasa mendakan masalah awal, ngahémat suku cadang sareng ningkatkeun kaluaran padamelan.

Pangropéa Biasa pikeun Suku Cadang Crusher

Inspections rutin pikeun Identipikasi Maké

Pamariksaan rutin penting pikeun ngaidentipikasi ngagemsuku cadang crushersateuacan ngakibatkeun gagalna alat. Pamariksaan rutin ngamungkinkeun para teknisi ningali tanda-tanda awal karusakan, sapertos retakan, bocor minyak, atanapi geter anu teu biasa. Pamariksaan ieu sering kalebet penilaian visual sareng panggunaan sénsor geter sareng suhu.

- Ngawaskeun kontinyu mantuan ngadeteksi masalah awal.

- Sensor geter sareng suhu ngaidentipikasi masalah sateuacan naék.

- Pamariksaan visual nembongkeun masalah sapertos bocor minyak.

Dynamox nyayogikeun solusi komprehensif pikeun ngawaskeun aset online. Dina hiji conto, analisis geter ngadeteksi baut crankcase ruksak dina crusher a, nyegah hiji shutdown unplanned. A teknisi negeskeun masalah nalika pamariksaan, nunjukkeun pentingna pamariksaan rutin.

Pamariksaan rutin tiasa ngirangan gagalna alat dugi ka 30%. pangropéa preventif ogé ngaronjatkeun efisiensi operasional jeung kaamanan, mastikeun crushers nedunan optimal dina kaayaan nuntut.

Beberesih jeung Nyabut lebu

Ngabersihan suku cadang crushermangrupakeun prakték pangropéa lugas acan vital. Akumulasi lebu, lebu, sareng résidu tiasa ngagancangkeun ngagem sareng cimata, ngirangan umur komponén kritis. Pembersihan rutin nyegah sumbatan sareng ngajamin operasi lancar.

Teknisi kedah difokuskeun kana daérah anu rawan akumulasi, sapertos saluran pakan, titik pembuangan, sareng sistem pelumasan. Ngagunakeun hawa dikomprés atawa parabot beberesih husus bisa éféktif miceun lebu tanpa ngaruksakkeun parabot. beberesih ditangtoskeun ogé ngaminimalkeun résiko overheating, nu bisa kompromi integritas bagian kawas bantalan jeung shafts.

A crusher bersih beroperasi leuwih éfisién, ngurangan setrés dina komponén tur nurunkeun likelihood breakdowns kaduga. Léngkah basajan ieu nyumbang sacara signifikan kana strategi pangropéa sakabéh.

Ngadegkeun Jadwal Pangropéa

A jadwal pangropéa well-rencanana ensures suku cadang crusher narima perawatan timely, nyegah maké jeung manjangkeun umur maranéhanana. Ngajadwalkeun tugas pangropéa ngamungkinkeun operator pikeun ngabéréskeun masalah sacara proaktif tinimbang réaktif.

- Studi kasus Titan America nunjukkeun pangurangan 30% dina downtime ngaliwatan pangropéa preventif, nunjukkeun mangpaat operasional tina jadwal rutin.

- Pit and Quarry nekenkeun yén pangropéa rutin sacara signifikan manjangkeun umur alat, ngirangan biaya anu luhur pikeun ngagentos komponén anu parantos.

- A tambang Afrika Selatan disimpen leuwih ZAR200.000 dina 10 bulan ku ningkatkeun strategi pangropéa na, showcasing kaunggulan ékonomi tina perawatan konsisten.

Jadwal pangropéa kedah kalebet pamariksaan rutin, beberesih, pelumasan, sareng ngagantian bagian. Operator tiasa nganggo alat digital pikeun ngalacak tugas sareng nyetél panginget, mastikeun henteu aya aspék pangropéa anu ditingali. Hiji pendekatan terstruktur ngurangan downtime, ngaronjatkeun efisiensi, sarta maximizes kinerja suku cadang crusher.

Lubrication pikeun ngaleutikan maké

Pentingna Lubrication ditangtoskeun

Lubrication ditangtoskeunpenting pisan pikeun ngurangan maké dina komponén crusher. Ieu ngaminimalkeun gesekan antara bagian pindah, mastikeun operasi lemes jeung nyegah overheating. Lubrication biasa ogé ngajaga ngalawan korosi, nu bisa ngaleuleuskeun komponén kritis kana waktu.

Statistik industri nunjukkeun pentingna ngawaskeun sistem pelumasan:

- Ngawaskeun suhu minyak pelumas mastikeun tetep dina kisaran idéal 100-130ºF (38-54ºC).

- Mariksa tekanan minyak pelumas mantuan ngadeteksi masalah kawas laju aliran low atawa clearances bearing kaleuleuwihan.

- Inspecting layar balik tank minyak pelumas nyegah rereged ti ngasupkeun sistem.

- Komitmen kana program analisa minyak ngadeteksi ngagem sareng kontaminasi awal.

- Ngajaga breathers hawa bersih ngajaga lebu kaluar tina sistem lubrication.

Prakték ieu mastikeun suku cadang crusher tetep dina kaayaan optimal, ngirangan résiko gagal anu teu kaduga.

Milih Pelumas anu Katuhu

Milih pelumas anu leres penting pisan pikeun maksimalkeun umur komponén crusher. pelumas kualitas luhur ngurangan gesekan sarta tahan hawa ekstrim, mastikeun kinerja konsisten. Panaliti nunjukkeun yén pelumasan biasa unggal 500 jam operasi sacara signifikan manjangkeun umur bagian kritis.

Analisis komparatif nembongkeun béda dina kinerja pelumas dina suhu luhur. Salaku conto:

- pelumas OAG ngajaga laju réduksi koefisien lubrication 83,2% dina 210 ° C, outperforming alternatif kawas RH-1 (78,4%) jeung HE-1 (67,2%).

- résistansi hawa punjul ngajadikeun OAG hiji pilihan alus teuing pikeun aplikasi nuntut.

Milih pelumas katuhu tailored kana kaayaan operasi husus ensures crushers beroperasi éfisién jeung reliably.

Kaunggulan tina Automated Lubrication Systems

Sistem pelumasan otomatis nawiskeun sababaraha kaunggulan dibandingkeun metode manual. Aranjeunna nganteurkeun jumlah pelumas anu tepat sacara konsisten, ngirangan résiko pelumasan kaleuleuwihan atanapi kirang. Ieu ngaminimalkeun ngagem sareng manjangkeun umur komponén.

Kauntungan utama kalebet:

- Nyegah nepi ka 75% tina gagal bantalan ngaliwatan lubrication konsisten.

- Ngurangan résiko langkung ti 50% dina sababaraha skenario.

Salaku tambahan, sistem otomatis ningkatkeun kasalametan tempat kerja ku ngabatesan paparan pagawe kana pelumas anu ngabahayakeun. Éta ogé ngurangan tugas-intensif kuli, sahingga operator fokus kana kagiatan pangropéa kritis lianna.

Ku ngadopsi sistem lubrication otomatis, usaha bisa ningkatkeun efisiensi, ngurangan downtime, sarta ngajaga suku cadang crusher maranéhanana ti maké prématur.

Dahar sareng Pangalusna Penanganan Bahan

Mastikeun Ukuran Bahan Bener

Ukuran bahan anu leres maénkeun peran anu penting dinangurangan maké on komponén crusher. Dahar bahan oversized atanapi undersized bisa nyieun sebaran stress henteu rata, ngarah kana maké prématur sarta poténsi karuksakan. Mastikeun yén bahan feed cocog sareng spésifikasi desain crusher ngaoptimalkeun kinerja sareng ngaminimalkeun galur anu teu perlu.

Data operasional nyorot mangpaat ukuran bahan anu leres:

- bahan feed disebarkeun merata ngaronjatkeun efisiensi crusher.

- Distribusi feed henteu rata naek kakuatan crushing puncak ka 8,8 unit, dibandingkeun jeung 5,3 unit kalawan dahar dioptimalkeun.

- Gaya crushing rata-rata turun tina 4,0 unit ka 3,7 unit dina kaayaan tuang anu leres.

Ku ngajaga ukuran bahan anu konsisten, operator tiasa ningkatkeun produktivitas bari manjangkeun umur komponén kritis sapertos suku cadang crusher.

Ngajaga Konsisten Dahar

Konsisten dahar ensures crusher nu ngoperasikeun mulus tanpa surges dadakan atawa interruptions. Pola dahar anu henteu teratur tiasa nyababkeun teu saimbangna, nyababkeun kaleuleuwihan dina komponén internal. Operator kedah nganggo feeders atanapi hoppers pikeun ngatur aliran bahan kana crusher nu.

A laju feed ajeg nyegah overloading sarta ngurangan résiko blockages. Ogé ensures yén crusher prosés bahan dina kapasitas optimal anak, ngaronjatkeun efisiensi sakabéh. Ngawaskeun rutin tinaparabot daharmantuan ngajaga konsistensi jeung nyegah downtime teu perlu.

Ngatur Aliran Bahan pikeun Ngurangan Stress

Ngatur aliran bahan éféktif ngurangan stress dina crusher sareng komponenana. Surges ngadadak atawa aliran bahan henteu rata bisa nyieun gaya-dampak tinggi, accelerating maké jeung cimata. Pikeun ngirangan ieu, operator kedah nganggo alat sapertos layar grizzly atanapi feeder geter pikeun nyortir bahan sareng ngahapus denda sateuacan aranjeunna ngalebetkeun crusher.

Mindahkeun bahan oversized ka crushers sekundér atawa pre-crushing aranjeunna ogé bisa mantuan nyaimbangkeun beban. pendekatan ieu ngaminimalkeun stress on crushers primér sarta ensures operasi smoother. manajemén aliran bahan ditangtoskeun henteu ngan ngajaga crusher tapi ogé ngaronjatkeun efisiensi sakabéh prosés crushing.

Sistem pangimeutan pikeun Deteksi Awal

Pangimeutan Geter pikeun Maké

Sistem ngawaskeun Getermaénkeun peran kritis dina detecting maké on komponén crusher mimiti. Sistem ieu ngagunakeun sénsor nirkabel pikeun ngalacak tingkat geter, nyayogikeun data sacara real-time ngeunaan kaséhatan alat.

- Dina hiji hal, sensor dipasang dina crusher Sandvik CH660 dicirikeun bolts overstressed atanapi leupas.

- Sistem ieu ngamungkinkeun tim pangropéa pikeun ngagentos sekrup anu rusak sateuacan aya kagagalan anu signifikan.

- Deteksi awal ngirangan résiko lirén anu teu dijadwalkeun sareng manjangkeun umur bagian kritis.

Ku ngaidentipikasi pola geter anu henteu teratur, operator tiasa ngatasi masalah sapertos misalignment atanapi kacapean komponén sateuacan naék. pendekatan proaktif Ieu ngaminimalkeun downtime sarta ensures suku cadang crusher tetep dina kaayaan optimal.

Pangimeutan Suhu pikeun Nyegah Overheating

Sistem ngawaskeun suhu ngabantosan nyegah overheating, anu tiasa nyababkeun pamakean kaleuleuwihan sareng kagagalan alat. Sénsor ngalacak suhu komponén konci, sapertos motor sareng sistem pelumasan, sareng micu alarm nalika ambangna ngaleuwihan.

- Salaku conto, alarm diaktipkeun nalika minyak kotak gear ngaleuwihan 75 ° C, nyegah ngagem gear disababkeun ku kagagalan pelumasan.

- Lubrication ditangtoskeun teu ukur dissipates panas tapi ogé ngajaga komponén tina rereged, enhancing produktivitas di crushers rahang.

- Tingkat panas abnormal sering nunjukkeun gesekan, lubrication goréng, atawa masalah listrik, sahingga ngawaskeun real-time penting.

Ku ngajaga suhu operasi idéal, sistem ieu ngajagaan komponén kritis sareng ngirangan kamungkinan perbaikan anu mahal.

Téknologi Canggih pikeun Deteksi Wear

Téknologi deteksi maké canggih ngungkit inovasi sapertos sensor IoT sareng pembelajaran mesin pikeun ngawas kinerja crusher. Sistem ieu nyadiakeun wawasan actionable, sangkan operator ngaoptimalkeun jadwal pangropéa sarta ngurangan biaya operasional.

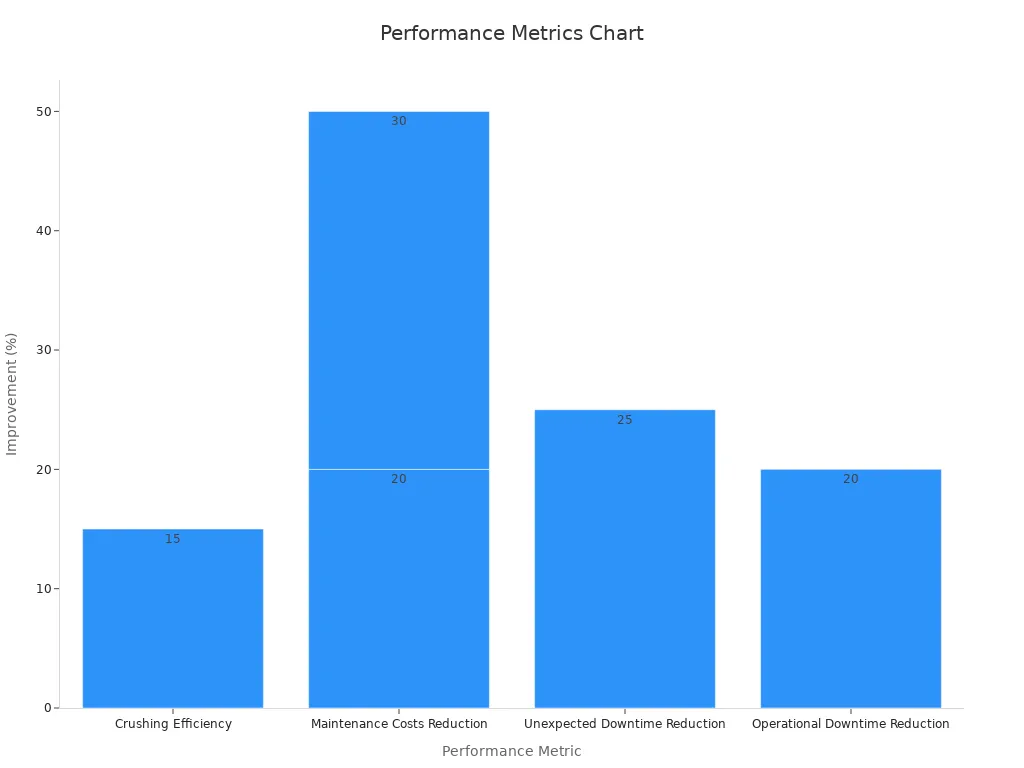

| métrik | Pamutahiran (%) | Sumber |

|---|---|---|

| Efisiensi Crushing | 15 | Jurnal Internasional Pertambangan sareng Téknik Mineral (2023) |

| Pangropéa Cost Réduksi | 20 | Jurnal Internasional Pertambangan sareng Téknik Mineral (2023) |

| Ngurangan Downtime teu kaduga | 25 | Asosiasi pikeun Manajemén Operasi (2022) |

| Ngurangan Downtime Operasional | 20 | Mordor AKAL |

| Pangropéa Cost Réduksi | 30 | Frost & Sullivan |

Téknologi ieu henteu ngan ukur ningkatkeun efisiensi crushing tapi ogé ngirangan biaya pangropéa sareng downtime anu teu kaduga. Ku ngadopsi sistem canggih, operator bisa mastikeun crushers maranéhanana beroperasi reliably jeung éfisién.

Pelatihan Operator sareng Manajemén Suku Cadang Crusher

Operator Pelatihan pikeun Pangropéa Preventative

Pelatihan operator dina pangropéa preventative ensures crushers beroperasi éfisién jeung ngurangan maké on komponén kritis. Ngadidik tanaga dina tugas rutin, sapertos pamariksaan sareng ngagantian bagian, nyababkeun rasa tanggung jawab pikeun alat-alat. Operator anu ngartos jadwal pangropéa tiasa ngaidentipikasi masalah poténsial awal, nyegah karusakan anu mahal.

- Latihan pangropéa rutin ngirangan kagagalan alat.

- Operator kéngingkeun kaahlian pikeun ngalaksanakeun pamariksaan sareng ngagentos bagian-bagian anu tos.

- Perawatan preventif ningkatkeun reliabilitas sareng efisiensi operasional.

Hiji tim well-dilatih nyumbang ka umur panjang tinasuku cadang crusherku alamat maké saméméh escalates. Pendekatan proaktif ieu ngaminimalkeun downtime sareng ningkatkeun produktivitas sadayana.

Pentingna Operasi Terampil

Operator terampil maénkeun peran penting dina ngajaga kinerja crusher. Operasi anu leres ngirangan setrés anu teu perlu dina komponén, manjangkeun umurna. Operator dilatih dina prakték pangalusna bisa ngaoptimalkeun aliran bahan, ngajaga dahar konsisten, sarta ulah overloading crusher nu.

Contona, tanaga terampil mastikeun ukuran bahan aligns kalawan desain crusher urang, nyegah maké henteu rata. Éta ogé ngawaskeun alat-alat pikeun irregularities, sapertos geter anu teu biasa atanapi lonjakan suhu, anu tiasa nunjukkeun masalah poténsial. Ku operasi crushers leres, pagawe terampil ngajaga komponén kritis tur ningkatkeun efisiensi.

Patuh kana Protokol Kasalametan sareng Pangropéa

Nuturkeun protokol kaamanan sareng pangropéa penting pisan pikeun ngirangan ngagem sareng mastikeun operasi anu aman. Operator kedah taat kana tungtunan produsén pikeun pamariksaan, pelumasan, sareng ngagantian bagian. Dijadwalkeun rutintugas pangropéa, digabungkeun sareng ukuran kaamanan anu ketat, nyiptakeun lingkungan kerja anu dipercaya sareng bebas bahaya.

Protokol ogé kalebet ngagunakeun alat anu leres sareng alat pelindung salami pangropéa. Salaku conto, nganggo sarung tangan sareng kacasoca nyegah tatu nalika nanganan bagian anu seukeut atanapi beurat. Sajaba ti, documenting kagiatan pangropéa ensures akuntabilitas tur mantuan ngalacak kaayaan suku cadang crusher kana waktu.

Ku prioritizing protokol kaamanan sarta pangropéa, operator bisa manjangkeun umur komponén tur ngajaga kinerja crusher konsisten.

Ngagantian Timely na Upgrades of Crusher Suku Cadang

Recognizing Nalika Bagian Peryogi Ngagantian

Ngagantian suku cadang anu tos waktosmangrupa kritik pikeun ngajaga efisiensi crusher sarta Ngahindarkeun breakdowns kaduga. Operator tiasa ngaidentipikasi nalika suku cadang kedah diganti ku ngawaskeun data kinerja sareng ngalaksanakeun pamariksaan rutin. Analitik canggih sareng sistem data langsung, sapertos anu ditawarkeun ku Metso, nyayogikeun wawasan sacara real-time ngeunaan kaséhatan alat. Alat-alat ieu ngabantosan ngadeteksi pola pakean sareng ngaduga iraha komponén-komponén caket kana tungtung umur jasana.

Ngajaga log akurat ogé maénkeun peran penting dina pembuatan kaputusan. Rékaman rinci ngeunaan kagiatan pangropéa sareng ngagantian bagian ngamungkinkeun operator ngalacak tren ngagem sareng ngarencanakeun ngagantian sacara proaktif. Sistem ngawaskeun otomatis salajengna ningkatkeun prosés ieu ku nganteurkeun panggeuing sacara real-time, ngamungkinkeun para operator pikeun ngabéréskeun masalah sateuacan naék. Jadwal pangropéa anu ditetepkeun saé mastikeun deteksi awal masalah poténsial, ngirangan résiko downtime anu teu direncanakeun.

Tip: Nunda pamariksaan atanapi panggantian tiasa nyababkeun gagalna mahal. Ngawaskeun proaktif sareng tindakan tepat waktu ngajaga efisiensi operasional sareng ngirangan biaya perbaikan.

Mangpaat Ngaronjatkeun kana Bahan Tahan Aus

Ngaronjatkeun kana bahan tahan ngagem sacara signifikan ningkatkeun daya tahan sareng kinerja komponén crusher. Pelat dampak tradisional, contona, biasana tahan 6-8 bulan, sedengkeun pelat dampak efisiensi tinggi tiasa dugi ka 18-24 bulan. Umur panjang ieu ngirangan frékuénsi panggantian, ngarah kana tabungan biaya anu ageung. Biaya pangropéa tiasa ngirangan dugi ka 40% nalika nganggo bahan anu tahan ngagem, sabab panggantian anu diperyogikeun langkung sakedik.

Mangpaat ngalegaan saluareun tabungan ongkos. Bahan tahan ngagem ningkatkeun umur jasa tina crushers, sering manjangkeunana ku 2-3 kali. Daya tahan ieu ngajamin kinerja anu konsisten sanajan dina kaayaan anu nungtut, ngaminimalkeun downtime sareng ningkatkeun produktivitas. Operator anu investasi dina bahan ieu henteu ngan ukur ngirangan biaya operasional tapi ogé ngahontal réliabilitas jangka panjang pikeun alatna.

Catetan: Sedengkeun investasi awal dina bahan tahan maké bisa jadi leuwih luhur, tabungan jangka panjang sarta kauntungan operasional jauh outweigh waragad upfront.

Mitrakeun sareng Panyadia Suku Cadang Dipercanten

Kolaborasi sareng panyadia suku cadang anu dipercaya ngajamin aksés kana komponén kualitas luhur sareng dukungan anu tiasa diandelkeun. Panyadia sareng reputasi pasar anu kuat ngabina kapercayaan sareng ngawangun kerjasama jangka panjang. Evaluasi lengkep ngeunaan suppliers, kalebet waktos pangiriman sareng ulasan pelanggan, ngabantosan operator milih mitra anu cocog sareng kabutuhan operasionalna.

Pembekal anu dipercaya ogé nyayogikeun pangropéa anu kuat sareng dukungan saatos penjualan, ngamaksimalkeun nilai suku cadang crusher. Ngawaskeun kinerja konsisten ngagunakeun indikator kinerja konci (KPIs) nawarkeun wawasan reliabiliti supplier jeung efisiensi alat. Pendekatan anu didorong ku data ieu ningkatkeun prosés pengadaan sareng ngajamin operasi anu lancar.

Tip: Ngajaga tingkat inventory optimum kalayan bantuan suppliers dipercaya ngaleutikan disruptions tur ngajaga kasadiaan parabot luhur 95%. Strategi proaktif ieu ngirangan downtime sareng résiko operasional.

Prakték pangropéa proaktif sacara signifikan ngirangan ngagem dina suku cadang crusher sareng manjangkeun umurna. Operator ngahontal hasil anu langkung saé ku ngalaksanakeun pamariksaan sadinten, pamariksaan pra-operasi, sareng pelumasan rutin bagian anu gerak. Téknologi pangropéa prediktif langkung ningkatkeun efisiensi ku ngadeteksi kasalahan awal sareng ngaoptimalkeun jadwal.Bagian ngagantian kualitas luhurningkatkeun reliabiliti, nyegah breakdowns kaduga. strategi ieu ngahemat waragad, ngaleutikan downtime, sarta mastikeun crushers beroperasi dina kinerja puncak. Usaha anu prioritas pangropéa mangtaun kauntungan jangka panjang, kalebet ningkat produktivitas sareng ngirangan résiko operasional.

FAQ

Naon anu jadi sabab paling umum maké on komponén crusher?

Maké mindeng hasil tina dahar teu bener, lubrication inadequate, atawa ukuran bahan goréng. Overloading crusher atawa ngagunakeun bahan sauyunan ogé bisa ngagancangkeun maké. Pamariksaan rutin sareng pangropéa ngabantosan ngaidentipikasi sareng ngabéréskeun masalah ieu langkung awal.

Sabaraha sering suku cadang crusher kedah dipariksa?

Teknisi kedah mariksa suku cadang unggal dinten atanapi mingguan, gumantung kana tungtutan operasional. Pamariksaan rutin pikeun retakan, bocor, sareng geter mastikeun deteksi awal ngagem. Jadwal pangropéa terstruktur ningkatkeun réliabilitas sareng ngirangan downtime.

Naha sistem pelumasan otomatis tiasa ngagentos pelumasan manual sadayana?

Sistem otomatis ningkatkeun efisiensi ku nganteurkeun pelumasan anu akurat sacara konsisten. Nanging, pamariksaan manual tetep penting pikeun pariksa kinerja sistem sareng ngatasi masalah anu teu kaduga. Ngagabungkeun duanana métode ensures panyalindungan optimal pikeun komponén.

Naon mangpaatna pikeun ningkatkeun ka bahan tahan ngagem?

Bahan tahan ngagem langkung lami sareng ngirangan frékuénsi ngagantian. Aranjeunna ningkatkeun reliabiliti crusher sarta waragad perawatan handap. Operator ngahontal produktivitas anu langkung saé sareng ngaminimalkeun downtime ku investasi dina komponén awét.

Kumaha operator bisa mastikeun dahar konsisten dina crushers?

Operator kedah nganggo feeder atanapi hoppers pikeun ngatur aliran bahan. Alat ngawaskeun nyegah surges atanapi interruptions. Konsisten dahar ngurangan setrés dina komponén tur ningkatkeun efisiensi crusher.

waktos pos: May-30-2025